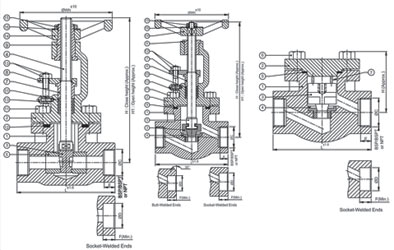

| API 602/ BS 5352 BOLTED BONNET /COVER FORGED VALVES |

| |

|

|

| |

| |

Heavy duty compact Out Side screw & York type, Bolted Bonnet / Cover, Rising stem, with Renewable Seatring valves, Piston lift check valves with spring loaded disc, resulting with most advance design features provide the ultimate in dependable, economic flow control. |

| |

| Compliance Standards |

| Parameter |

Compliance to |

| Design |

API 602 /BS 5352/ ASME B 16.34 |

| Pressure Temperature Rating |

ASME B 16.34 |

| Screwed Ends Dimensions |

ASME B 1.20.1 |

| Socket Weld Ends Dimensions |

ASME B 16.11 |

| Butt Weld Ends Dimensions |

ASME B 16.25 |

| Inspection & Testing |

ISO 5208 /API 598/ BS 6755 Part I |

|

| Part No. |

Part |

Material |

| 1 |

Body |

A 105/ A 182 F 304/ F 304L/ F 316/ F 316L/ F 11 / F 22/ A 350 LF 2 |

| 2 |

Bonnet / Cover |

A 105/ A 182 F 304/ F 304L/ F 316/ F 316L/ F 11 / F 22/ A 350 LF 2 |

| 3 |

Wedge/ Plug@ |

A 105/ A 182 F 304/ F 304L/ F 316/ F 316L/ F 11 / F 22/ A 350 LF 2 |

| 4 |

Stem |

A 276 410/ 304/ 316 |

| 5 |

Seat Rings |

A 182 F6a/ A 182 F 304/ F 304L/ F 316/ F 316L/ F 11/ F 22/ A 350 LF 2 |

| 6 |

Back Seat Bushing |

Integral |

| 7 |

Gland |

A 276 410/ A 182 F 304/ A 182 F 316 / LF 2 |

| 8 |

Gland Flange |

A 105/ A 182 F 304/ F 304L/ F 316/ F 316L/ F 11 / F 22/ A 350 LF 2 |

| 9 |

Stem Nut |

A 439 D2 / Al. Bronze |

| 10 |

Lock Nut |

Carbon Steel / SS 304 |

| 11 |

Gland Packing |

Grahited Asbestos / Grafoil / PTFE |

| 12 |

Bonnet Gasket |

Spiral Wound SS 304/ 316 with Asbestos / Teflon or Grafoil |

| 13 |

Gland Eye Bolt & Nut |

SS 410 / SS 304 |

| 14 |

Hand Wheel |

Carbon Steel |

| 15 |

Hand Wheel Nut |

Carbon Steel |

| 16 |

Studs / Bolts |

A 193 Gr. B7 / Gr. B7M/ Gr. B8 / Gr. B8M/ L7 |

| 17 |

Nut |

A 194 Gr. 2H/ Gr. 2HM/ A 194 8/ A 194 8M/ A 194 4/7 |

|

| |

@ CS & Alloy Steel Disc and Seat Rings will be overlayed with 13% Cr. Or Stellite 6 as per customer specifications

|

| |

| ASME 800 CLASS - GATE VALVES |

| |

6 |

10 |

15 |

20 |

25 |

32 |

40 |

50 |

| L - SP |

85 |

85 |

92 |

105 |

125 |

125 |

135 |

- |

| L - RP |

85 |

85 |

92 |

92 |

105 |

125 |

125 |

135 |

| P - SP |

6 |

9 |

12 |

17.5 |

22.5 |

29.5 |

35 |

- |

| P - RP |

6 |

6 |

9 |

12 |

17.5 |

22.5 |

29.5 |

35 |

| H (Appx.) |

165 |

165 |

165 |

175 |

195 |

265 |

265 |

275 |

| ØW |

85 |

85 |

85 |

85 |

150 |

150 |

150 |

150 |

| Wt. (Appx.) |

2 |

2 |

2 |

3 |

3 |

8 |

8 |

10 |

|

| ASME 1500 CLASS - GATE VALVES |

| |

6 |

10 |

15 |

20 |

25 |

32 |

40 |

| L |

92 |

92 |

92 |

105 |

125 |

125 |

135 |

| P |

6 |

6 |

9 |

12 |

16 |

19 |

27 |

| H (Appx.) |

175 |

175 |

175 |

195 |

265 |

275 |

275 |

| ØW |

90 |

90 |

90 |

100 |

150 |

150 |

150 |

| Wt. (Appx.) |

3 |

3 |

3 |

4 |

8 |

10 |

10 |

|

| ASME 800 CLASS - GLOBE VALVES |

| |

6 |

10 |

15 |

20 |

25 |

32 |

40 |

50 |

| L - SP |

85 |

85 |

92 |

105 |

125 |

125 |

135 |

- |

| L - RP |

85 |

85 |

92 |

92 |

105 |

125 |

125 |

135 |

| P - SP |

6 |

9 |

12 |

17.5 |

22.5 |

29.5 |

35 |

- |

| P - RP |

6 |

6 |

9 |

12 |

17.5 |

22.5 |

29.5 |

35 |

| H (Appx.) |

165 |

165 |

165 |

175 |

195 |

265 |

265 |

275 |

| ØW |

90 |

90 |

90 |

100 |

150 |

150 |

150 |

150 |

| Wt. (Appx.) |

3 |

3 |

3 |

4 |

8 |

8 |

11 |

11 |

|

| ASME 1500 CLASS - GLOBE VALVES |

| |

6 |

10 |

15 |

20 |

25 |

32 |

40 |

| L |

92 |

92 |

92 |

105 |

125 |

130 |

135 |

| P |

6 |

6 |

11 |

15 |

19 |

27 |

31 |

| H (Appx.) |

175 |

175 |

175 |

190 |

250 |

250 |

250 |

| ØW |

90 |

90 |

90 |

100 |

150 |

150 |

150 |

| Wt. (Appx.) |

3 |

3 |

3 |

4 |

8 |

8 |

11 |

|

| ASME 800 CLASS - CHECK VALVES |

| |

6 |

10 |

15 |

20 |

25 |

32 |

40 |

50 |

| L - SP |

85 |

85 |

92 |

105 |

125 |

125 |

135 |

- |

| L - RP |

85 |

85 |

92 |

92 |

105 |

125 |

125 |

135 |

| P - SP |

6 |

9 |

12 |

17.5 |

22.5 |

29.5 |

35 |

- |

| P - RP |

6 |

6 |

9 |

12 |

17.5 |

22.5 |

29.5 |

35 |

| H (Appx.) |

55 |

55 |

55 |

70 |

105 |

105 |

115 |

115 |

| Wt. (Appx.) |

3 |

3 |

3 |

4 |

8 |

8 |

11 |

11 |

|

| ASME 1500 CLASS - CHECK VALVES |

| |

6 |

10 |

15 |

20 |

25 |

32 |

40 |

| L |

92 |

92 |

92 |

105 |

125 |

130 |

135 |

| P |

6 |

6 |

11 |

15 |

18 |

27 |

31 |

| H (Appx.) |

65 |

65 |

65 |

70 |

105 |

115 |

115 |

| Wt. (Appx.) |

4 |

4 |

4 |

4 |

7 |

10 |

10 |

|

Options

- For Low Temperature and Cryogenic Services Extended Bonnet as per BS 6364 available

- Below Seal for critical service and hazardous media

- Welded on Flanges/ Welded Bonnet / Cover Construction

|

Every individual valve manufactured at HK is inspected and pressure tested, for which test certificates are provided according to ISO 10474/EN10204 3.1 B

Due to continuous product development the products, texts, photographs, graphics and diagrams in this broucher may be subject to alteration by HK without prior notice or reasons being given.

|